Industry status and price trend

As a high-end high-temperature material, TZM alloy (molybdenum titanium zirconium alloy) continues to grow in demand in the aerospace, semiconductor and energy fields. The global market presents an oligopoly pattern, with major manufacturers concentrated in industrial powers such as the United States, Germany and Japan. China has achieved domestic substitution in some mid-to-high-end products.

Price influencing factors:

TZM Raw material fluctuations: Molybdenum prices account for 40-50% of the cost, and molybdenum price fluctuations in 2023 will significantly affect alloy prices

Capacity restrictions: High-end product capacity is limited, and special specifications can reach a premium of 30-50%

Application expansion: The semiconductor industry’s demand for high-purity TZM has increased by more than 15% annually

In the past five years, TZM metal prices have shown a “W-shaped” trend and are currently stable at US$140-180/kg. It is expected to maintain an annual growth rate of 5-8% from 2024 to 2025.

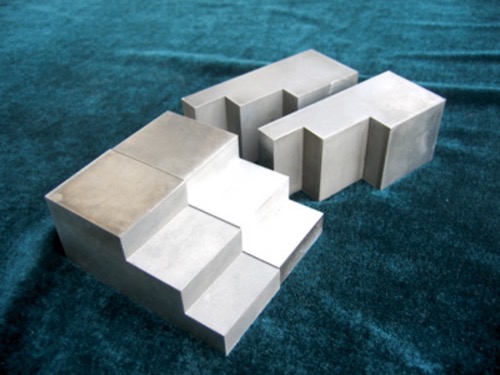

Product Core Value Analysis

The high price of TZM alloy is due to its irreplaceable performance advantages:

The strength at high temperature of 1200°C is twice that of conventional molybdenum alloys

The recrystallization temperature is as high as 1400°C

Excellent thermal conductivity (138W/(m·K)) and dimensional stability

Process determines value:

Process Cost coefficient Key advantage

Conventional sintering 1.0x basic performance

Hot isostatic pressing 1.5-2.0x Density ≥99.5%

Electron beam melting 2.0-2.5x Ultra-high purity

Life cycle cost advantage:

Aviation parts reduce weight by 30%, and fuel efficiency is significant

Semiconductor thermal field life is 5-8 times that of graphite

Glass furnace maintenance cycle is extended by 2-3 times

Purchase time:

Prices are usually lower in Q2 each year

Follow the trend of LME molybdenum futures

Follow the production capacity dynamics of major manufacturers

TZM alloy is a typical high-value functional material. Purchasing decisions should go beyond unit price considerations and comprehensively evaluate the full-cycle value of performance, life and service. Establishing strategic cooperation with suppliers with strong technical capabilities is an effective way to achieve cost optimization.

Keywords:

tzm material